Bitronics Power Measurement

Easy to use, hard to beat.

Dependable precision from the pioneers of digital substation metering.

Simple setup and configuration

Bitronics meters emphasize simplicity with intuitive touch-front displays and web-pages for setup, universal wiring, and crisp LED displays. With optional external CTs, you can install without taking an outage.

Above-and-beyond accuracy

All products are individually calibrated to maintain 0.2s precision, even when you use external split-core CTs.

Always made in the USA

All Bitronics meters have been designed, built and tested in our Bethlehem, PA facility since 1982. With a MTBF of 40 years, you can rely on our products when you need them the most. All Bitronics come with a 10-year “no hassle” warranty.

Experts on call

Our engineers can assist you with more complex applications, including event recording, IEC 61850, and power system analysis.

"…a product that keeps the simple things virtually effortless and makes the hard things pretty easy too… "

Chris, SCADA Engineer

Panel Meters & Transducers

With simplified wiring, universal power supplies, capacitive-touch buttons and web-based configuration, the Bitronics 50 and 60 Series SCADA Meters and Transducers are simple to order, configure, and install.

Learn more

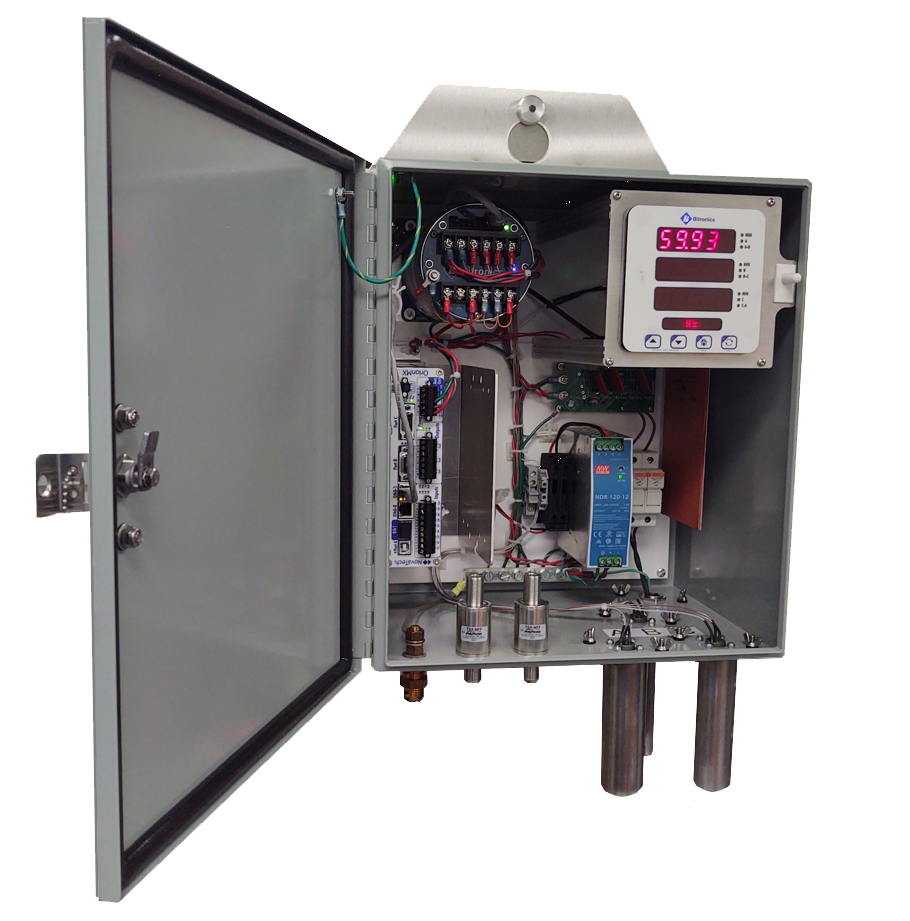

Distributed Grid Monitor

The DGM is a power monitoring solution–also known as a “primary in a box” that consists of a Bitronics M661 meter, matched Lindsey LEA (low energy analog) sensors, and cabling, plus an optional OrionMX RTU for cybersecurity, I/O, and automation functions.

Learn more

Universal Display

The Bitronics Universal Display connects easily to any substation IED via DNP or Modbus Client (Serial or Ethernet) to display measurement values residing in those IEDs.

Learn more

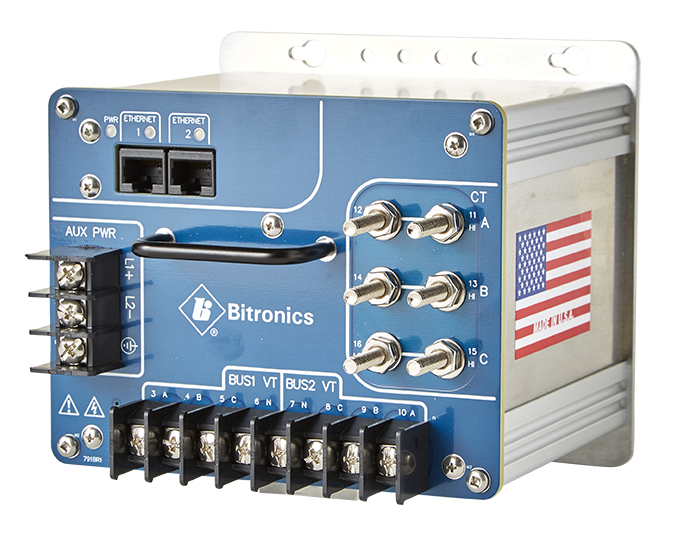

PowerPlex II

The PowerPlex II is an automation transducer with two sets of three-phase voltages and 1-cycle measurement update speeds suitable for generator and tie synchronization applications.

Learn more

Let’s talk

Call us today at 844.NovaTech (668-2832)

Or please fill out this form and someone will get back to you shortly.