Solving automation challenges for the evolving power grid

NovaTech Automation produces the easiest to use and best supported automation products and solutions for electric utilities. These products are at the core of our engineered systems that can be found in the substation, on pole tops, in the enterprise, and at the grid edge.

10-year no hassle

warranty

Always made in

the USA

Net zero

committed

Of our clients would

recommend us to a colleague

Trusted by companies who power the world

Out of the box and into the server

Be the first to know

Solving automation challenges for the evolving power grid

Explore our solutions roadmap

Introducing the new OrionMX AC Meter Card

Integrate power measurements to vault and pole top applications

Engineering net zero

Learn about our commitment

See you in Anaheim, booth 4629

Learn more

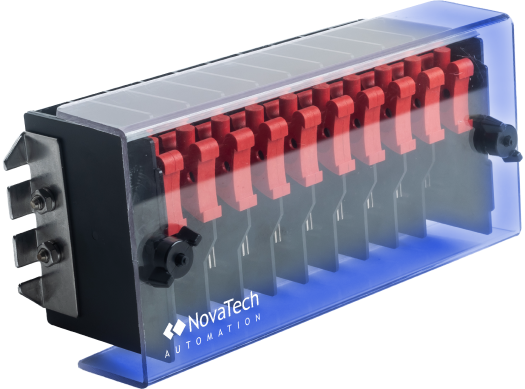

New! W3TS Test Switch now available.

Learn more about their unmatched reliability and safety

Reliable time in less time

Multi-constellation precision with simple configuration, now with sub-microsecond accuracy via PTP

Journey to decarbonization

Watch how we’re monitoring power usage

Engineering climate resilience

The Philippines: The front lines of climate changeNews

Training and Events

Let’s talk

Call us today at 844.NovaTech (668-2832)

Or please fill out this form and someone will get back to you shortly.